Makita's new generation of machines are more powerful than ever before, but thanks to Anti-Vibration Technology (AVT™) they also break new ground in vibration protection.

HOW AVT WORKS

The benchmark in vibration reduction Makita demolition tools are among the best in the world. Working with the users to solve the problem of vibration Makita's AVT products have been designed in close relation to users' needs at site level.

FOCUSING ON THE THREE D'S: DIALOGUE, DEVELOPMENT & DELIVERY

No effort has been spared to ensure that our products provide the professional user with reliable, long lasting power. The diagram on the right shows the benefits of AVT at work and how we have managed to apply this revolutionary new technology to two of our most heavy duty hand held tools.

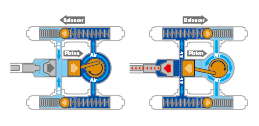

INITIAL PROTECTION

The AVT mechanism works by transferring air around a series of chambers which, in turn, pushes a counterbalance in the opposite direction to the piston, thereby cancelling out the vibration the piston would have created otherwise.

SECONDARY PROTECTION

Shock absorbing handles are also used on appropriate tools for added protection.

HAMMERS (AVT)

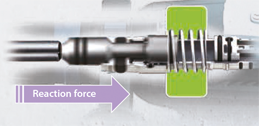

ACTIVE DYNAMIC VIBRATION ABSORBER |

DAMPER SPRING |

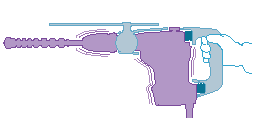

VIBRATION ABSORBING HOUSING |

|

|

|

| Ensures operation with extremely low vibration. Allows tool design with flat body sides for better handling. | Absorbs reaction force caused by drill bit at the moment of impact. | This is the new AVT mechanism advanced from the current "Vibration absorbing handle". The level of vibration is further reduced by completely separating the machine holding section from the motor/transmission section. |

BREAKERS (AVT)

COUNTER WEIGHT MECHANISM |

VIBRATION ABSORBING HOUSING |

SOFT NO LOAD FUNCTION |

|

|

|

| Reduces vibration during chipping operation. | Providing a practical combination of high power and low vibration. | Reduces vibration of tool body when idling, accordingly decreases the amount of vibration to operator’s hands during a day’s operation. Minimizes deflection of bit tip from aiming point when starting chipping. |